Full-Service Tool Room – Backbone of Our Operation

Miro Manufacturing offers comprehensive tooling services with a world-class, full service, on-site tool room. We take things to the next level.

Trusted Tooling Company for Challenging Jobs

Miro has taken over the production of stamped parts from large companies who said the part couldn’t be made per print with existing tooling. Our tool room reviewed the project, proving the original outside assessment incorrect. Our stamping department then produced parts per print.

Tooling worn out and struggling to make parts per print?

We will rescue your tooling and stamp your parts while we build the replacement tooling. Once complete, we will PPAP the new tooling and seamlessly switch over without interrupting your production requirements. Let Miro ease the burden of resourcing your current production.

Industrial Tooling Services Include Custom Design

Miro provides full in-house tooling design services featuring SOLIDWORKS. Part simulation is performed as necessary. As-built designs are kept on file for any future engineering changes as well as manufacture of needed replacement components. This translates to reduced downtime.

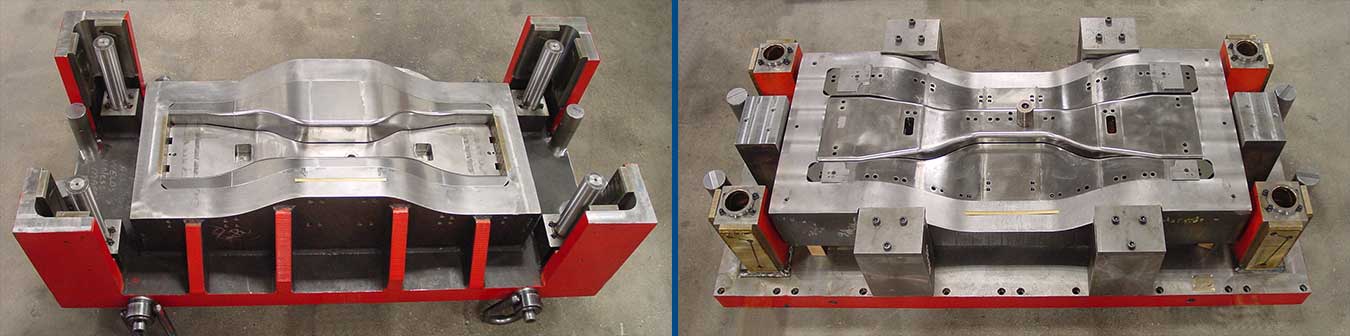

Left: Upper half of draw die. Right: Lower half of draw die

Production Tooling Manufacturing

We have designed and built many different types of tooling. Our knowledgeable and experienced tool makers excel at progressive, blank, form, draw and compound dies. Our tooling has produced precision metal stampings from a variety of metals:

- stainless and carbon steel including high strength low alloy

- aluminum

- brass, copper, nickel and many other materials

- thicknesses ranging from 0.005” to 0.500” thick

Precision Machine Tooling Expertise

We maintain current technology in wire EDM and CNC machining. In turn this provides greater manufacturing efficiency and accuracy when building tooling. This helps to reduce overall costs. Our toolmakers are experts when it comes to in-die tapping, in-die fastener insertion, sensors, prototype tooling, fixtures and gages. Miro’s high quality, cost-effective approach to tooling keeps production up and operation costs down.

Miro can help…

Whether your project involves new tooling, or you need to move the work due to supply chain or quality issues, contact Miro. We have developed a reputation for reliability as a tool and die maker. That experience translates into precision, repeatability and consistent quality for all the metal stampings we produce. Get Miro involved from the start.

Tooling Manufacturer Serving Industry Nationwide

Located in Waukesha, near Milwaukee, Miro Manufacturing serves customers throughout Wisconsin and coast to coast. Manufacturers call on us to provide industrial tooling solutions others can’t.

Submit an RFQ, give us a call, or contact us online with questions.

View our “Capabilities and Equipment List” for a complete list of our Tooling Services equipment.