Tool & Die Design Services that Promote Reliable & Economical Manufacturing

Miro Manufacturing provides in-house tool and die design services making us one of the only full-service contract metal stamping solutions in the nation. Trust your tooling design to Miro’s team of experts with over 30 years of experience.

Our Comprehensive Tool Design Process

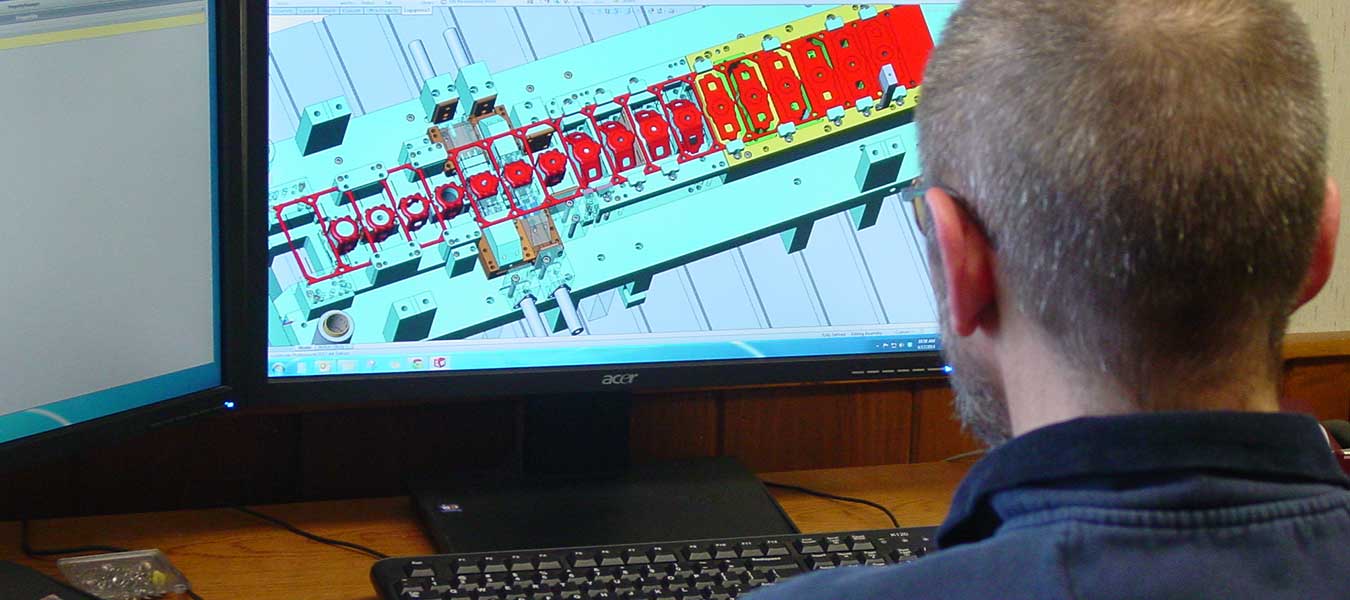

The part material, processes required to make the part, and estimated annual volume are all taken into consideration during the design stage. Our team guides your project from concept through final die design. We begin with your data, accepting industry standard file formats such as STEP, IGES and Parasolid. These files are then used as the basis for designing required prototype and production tooling, fixtures, and gages.

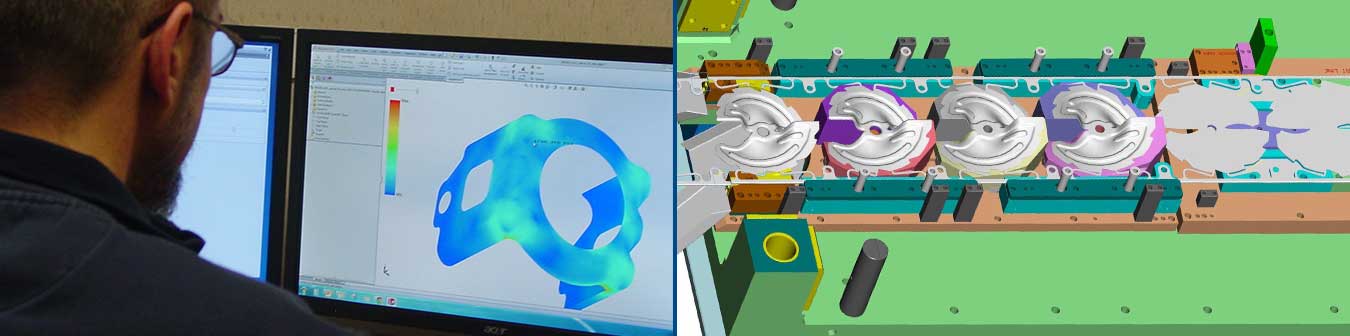

Our in-house design team uses SOLIDWORKS with Logopress3 to create innovative designs that reduce manufacturing lead times and increase productivity.

Experts from across our design, tooling, and production teams collaborate together to look at the whole process and create the most reliable, robust, and easy to maintain tooling die.

Tool Design Experts

The combined capabilities of onsite design and our onsite tool room sets Miro apart from most stampers.

In addition to the expertise of our own team, Miro accommodates large, multiple part projects by employing the services of proven outside design firms when required. We also work in conjunction with simulation professionals to provide comprehensive process engineering when circumstances dictate.

Tooling Design Services for Industry Nationwide

Located in Waukesha, near Milwaukee, Miro Manufacturing serves customers throughout Wisconsin and across the United States.

Submit an RFQ, give us a call, or contact us online with questions.

View our “Capabilities and Equipment List” for a complete list of software used by our designers.