Tooling is essential for all manufacturing processes. It involves creating the necessary fixtures to produce parts and products. The process requires a deep understanding of various techniques, from material selection to machining and final assembly.

Because the quality of your tooling can make or break your manufacturing operation, selecting the right tooling vendor is crucial. Your vendor needs to know which techniques are appropriate for your project to ensure optimal results and have the capability to execute them. This includes making informed decisions about materials, processes, and the sequence of operations. A knowledgeable tooling partner can guide you through these choices, optimizing project execution.

Basics of Tooling Design

Tooling design is a sophisticated process that leverages advanced technologies and methodologies.

Here are some of the key components involved:

CAD/CAM Technology

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) revolutionized tooling design. With CAD, draftsmen can quickly generate precise tool designs and even simulate them so that every detail can be accounted for before production begins. CAM facilitates the automated control of machinery, translating CAD designs into physical tools with high accuracy.

CNC Machining

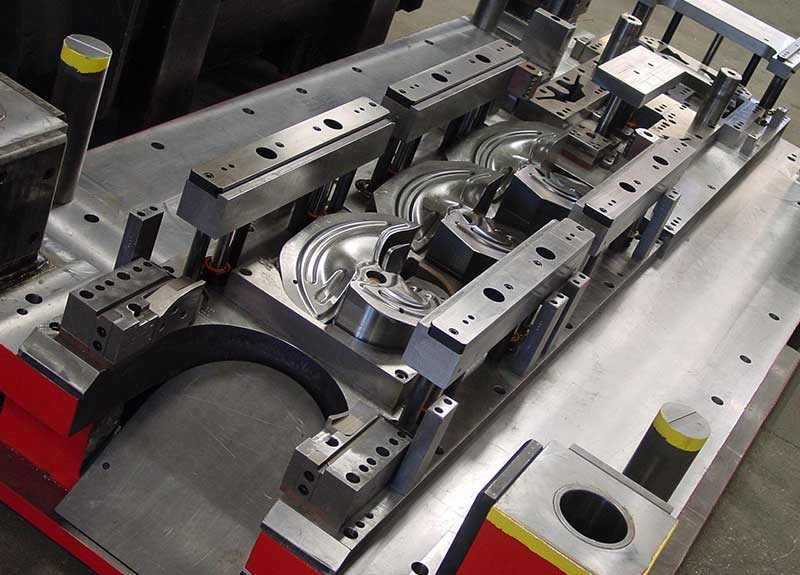

CNC (Computer Numerical Control) machining is a pivotal technique in tooling design. Machinists are still required. However, instead of manually operating the machines, the machinists use computers to control machine tools. CNC programming is capable of producing highly detailed, complex parts. Because CNC machine tools need minimal human intervention to operate, they machine parts more efficiently and consistently.

Additional Techniques

Beyond CAD/CAM and CNC machining, wire EDM is often used to produce high-precision die set components. Being able to make exacting cuts less than the thickness of a human hair, electrical discharge machining lends itself well to this application.

What Miro Manufacturing Considers When Designing Tooling for Your Project

To maintain operational efficiency when designing and manufacturing your tooling, Miro considers several factors. Your input is invaluable, as it helps us to determine the most cost-effective methodology to utilize when designing and manufacturing stamping dies.

Here are some key elements we evaluate:

Material Selection

Miro utilizes the best industry-standard materials in the construction of our stamping tools. This ensures durability, repeatability, and application longevity for our customers.

Production Volume

Required production volumes greatly influence the build of the tool. Lower volume annual usage can allow for less complex, more economical hand transfer tooling may be warranted depending on the complexity of the part. Higher volumes may necessitate more advanced tooling options but overall returns in manufacturing efficiency must justify the investment.

Cost-Efficiency

As mentioned, cost is always a factor when it comes to a purchase. Miro always tries to offer the best return on investment for a given tooling situation. We work closely with our customers to offer cost-saving options that do not compromise the production of a quality finished item. Miro’s experience allows us to be application-smart as well as cost-effective. Our tooling repeatably produces parts to spec time and time again over the functional lifetime of the die.

The Miro Difference in Tooling Design

Expert tooling design is a vital component of successful manufacturing. It enhances efficiency, improves product quality, and reduces costs, ultimately contributing to the competitiveness and profitability of your business.

Founded in 1988 as a small, family-owned tool & die shop, Miro Manufacturing has evolved to encompass a broad range of services, including fabrication, CNC machining, and welding. (See some of our newest machines that we added to better serve customers like you!) This evolution is a testament to our commitment to excellence in tooling design, honed over decades of experience.We are dedicated to delivering top-notch tooling solutions tailored to your needs. Trust us to be your partner in achieving manufacturing excellence – let us quote your next tooling design project: https://miromfg.com/rfq/.