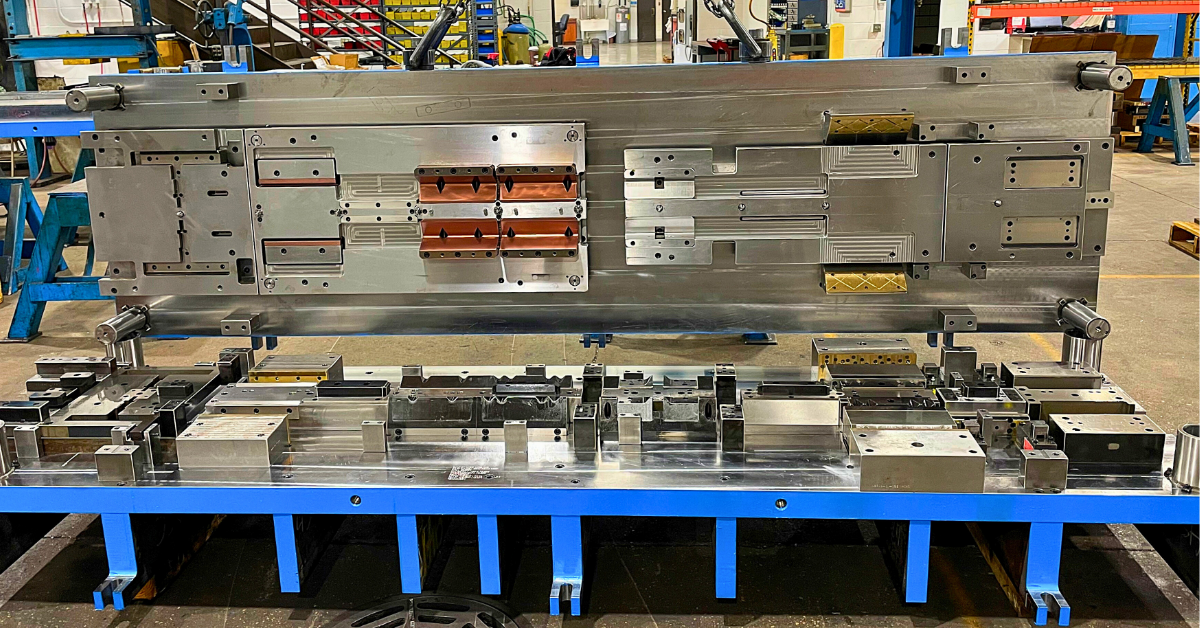

Miro Manufacturing: Your Proven Partner for High-Precision Tooling and In-House Metal Stamping Solutions

Why Tooling Manufacturing Matters

At Miro Manufacturing, tooling isn’t an afterthought, it’s our foundation. Established in 1988 as a tool and die shop, we’ve built our business on the precision, discipline, and deep technical know-how that tooling demands. Over time, we’ve evolved into a full-service contract manufacturer, but tooling remains at the heart of everything we do.

Our in-house tooling manufacturing capabilities give us—and our customers—a strategic advantage in production stamping projects. Here’s how.

The Power of In-House Tooling

When you partner with Miro, your tooling is designed with the finished part and the entire manufacturing process in mind.

- Tailored to Your Part, Optimized for Our Presses: Every tool we make is engineered not just for your geometry, but also for the exact press that will run it in-house. Miro utilizes advanced software to provide simulations to enhance our tooling designs as needed.

- Reduced Downtime for Tool Repairs: There’s no wait for an external vendor when tooling needs sharpening, repair, or modification. Tooling travels approximately 300 feet from Miro’s press department to our tool room, saving days in turn time and minimizing disruption to your production schedule.

Faster Response, Lower Downtime

Tooling issues can shut down production lines. With outsourced tooling, you’re often stuck waiting for it to be shipped, inspected, and repaired off-site. At Miro, we don’t have that problem, and neither do you.

- Immediate Tool Diagnostics: Our toolmakers can assess and troubleshoot issues in real time, with no need to send tools off-site.

- Proximity-Driven Efficiency: Tooling designed, built, and serviced under one roof means we can get your line running again faster, whether it’s a chipped punch, alignment issue, or design modification.

- Reduced Lead Time: By avoiding delays tied to external tool shops, we can better control your production schedule. Fewer outside sources mean fewer opportunities for something to go wrong.

Cost-Effectiveness and Quality Control

Tooling manufactured in-house at Miro is built to perform long-term. Miro’s commitment pays dividends throughout the life of your part.

- Built to Miro Standards: Our tools are made from quality tool steels that fit your application.

- Tighter Tolerances, Higher Consistency: Because we control both the tool build and the production process, we can hold tighter tolerances and maintain uniformity across all the tool components. This leads to a consistent, superior production part.

- Cost Savings Over the Long Term: Our tooling is designed for long service life. We engineer our dies to minimize scrap and reduce maintenance costs. The result? Lower total cost of ownership.

- Quality Inspections at Every Stage: From raw stock through final tool validation, everything is inspected under one roof. We never ship a tool or a part until it meets both our and our customer’s standards.

Partnering With Miro From “Start to Part”

Our “Start to Part” philosophy means we partner with you early, because the earlier we’re involved, the more we can help optimize.

- Collaborative Engineering Support: We work directly with your engineering team to identify design features that impact manufacturability and suggest modifications that streamline the manufacturing process.

- One Tool, One Team, One Seamless Process: From the design model to the final stamped part, Miro manages the entire production process. No handoffs, no delays, and no compromises on quality.

The Miro Difference

There are plenty of companies that build tooling. There are plenty that offer metal stamping. But few offer both, in-house, with the speed, precision, and accountability Miro delivers.

- Faster Launches: By managing the entire production process from concept to completed part, we drastically reduce the time it takes to get new products to market.

- Fewer Delays: On-site troubleshooting and rapid response to tooling needs prevent downtime and missed deadlines.

- Better ROI: The upfront investment in Miro tooling is returned many times over through better part quality, lower scrap rates, and reduced maintenance costs.

At Miro, tooling is the cornerstone of every stamped part we deliver. That’s why some of the biggest names in industries like power distribution, medical equipment, and appliances trust Miro as their long-term manufacturing partner.

Let’s Get to Work

Whether you’re reshoring a project, replacing an underperforming supplier, or launching a new product line, Miro Manufacturing is ready to take your stamping and tooling project from start to part.

Discover the difference in in-house tooling and stamping. Start your next project with Miro. Contact us today to request a quote.