At Miro Manufacturing, we believe that continuous growth and innovation are at the core of industrial manufacturing success. In 2024, we made strategic investments in our equipment, facilities, and leadership to strengthen our capabilities and provide even greater value to our customers. This year has been a testament to our commitment to staying at the forefront of the industry, ensuring that we deliver high-quality, cost-effective solutions for large-scale industrial manufacturers in power distribution, appliances, medical, and other key sectors.

Fabrication: Strengthening Our One-Stop Shop Capabilities

In 2023, Miro Manufacturing expanded our stamping facilities and added a 660-ton press to our equipment lineup. In response to customer demand, Miro has continued expanding our fabrication capabilities to solidify our position as a true one-stop contract manufacturing partner. Our advanced metal fabrication services, which include laser cutting, waterjet cutting, press brake forming, welding, and mechanical assembly, enable us to streamline production, reduce lead times, and provide turnkey solutions for our customers. By keeping these processes in-house, we minimize supply chain complexity and ensure superior quality control from start to finish.

New Equipment Investments: Boosting Efficiency and Precision

2024 was a milestone year for Miro Manufacturing, with major additions to our equipment lineup. These investments improve precision, increase production efficiency, and allow us to better serve our growing customer base. Here are some of the key additions:

Turret Press

Our Motorum M2044TS CNC turret press delivers highly efficient low- to mid-volume sheet metal production. By eliminating the need for dedicated stamping tooling, this machine provides a cost-effective solution for customers looking to prototype and scale up production as demand increases. (Click here to download the specifications for our turret press and all our machines.)

Welding Cobot

Automation continues to be a priority at Miro, and the addition of a programmable welding cobot has enhanced our welding capabilities. This collaborative robot enables precise, repeatable welds while increasing throughput. It ensures high-quality welds with minimal variation, reducing rework and improving overall efficiency. (Read more about our cobot here.)

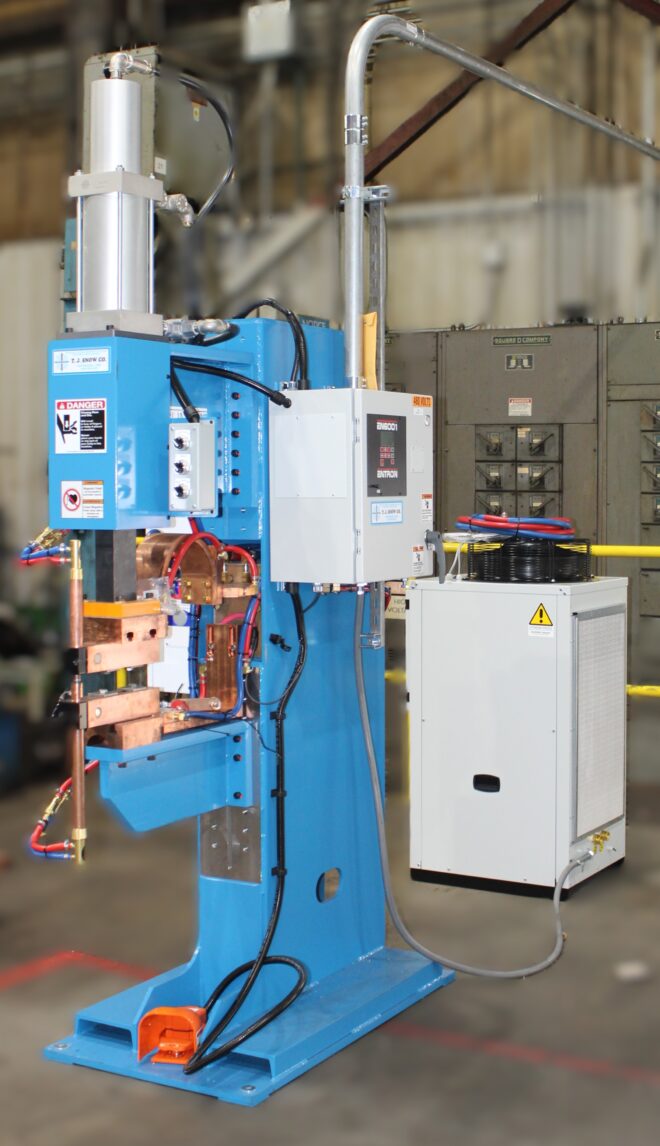

Resistance Welder

We introduced a Slim Line Ram Type Resistance Welder, which increases efficiency for high-volume welding projects. This machine enhances productivity by delivering rapid, high-quality welds that eliminate the need for filler materials and minimize heat distortion.

330T Press Brake

Our new 330-ton SafanDarley E-Brake Ultra features servo-electric bending technology and a 14’ bed, allowing us to form large sheet metal components with unmatched precision. Its ultra dual drive system enables higher productivity, ensuring consistent, accurate bends across the entire length of the part.

Mitsubishi 8000-Watt Fiber Laser

We expanded our laser cutting capabilities with a state-of-the-art Mitsubishi 8000-watt fiber laser, capable of cutting aluminum up to ½”, stainless steel up to ¾”, and mild steel up to 1”. Its automation system enhances efficiency, reduces material waste, and supports high-volume production runs.

Facility Investments: Optimizing Manufacturing Flow

Beyond new equipment, we’ve continued to refine our facility layout and manufacturing flow to maximize efficiency. Every square foot of our production space is optimized to improve throughput and reduce downtime. By refining our workflows, we are not only increasing production speed but also reducing costs for our customers, ensuring the best possible value for their manufacturing needs. (Read about our expansion that added over 125,000 square feet to our facilities here.)

Leadership Transition: A New Era for Miro Manufacturing

2024 marked an exciting leadership transition at Miro Manufacturing. Jeff Brown has transitioned to CEO, while Adam Brown has stepped into the role of company President. This leadership shift reflects Miro’s ongoing commitment to innovation and long-term strategic growth. Under their leadership, Miro will continue to push boundaries in industrial manufacturing, maintaining the high standards that have made us a trusted partner for leading global manufacturers.

The Road Ahead: Partnering for Success in 2025

As we move into 2025, we remain committed to delivering high-quality, cost-effective solutions that drive success for our customers. Our investments in fabrication, automation, and facility enhancements have positioned us to take on even more complex projects while maintaining our reputation for precision and reliability.

If you’re looking for a trusted partner in industrial manufacturing that offers advanced fabrication, machining, and stamping capabilities, Miro Manufacturing is ready to help. Request a quote today and experience the Miro difference.