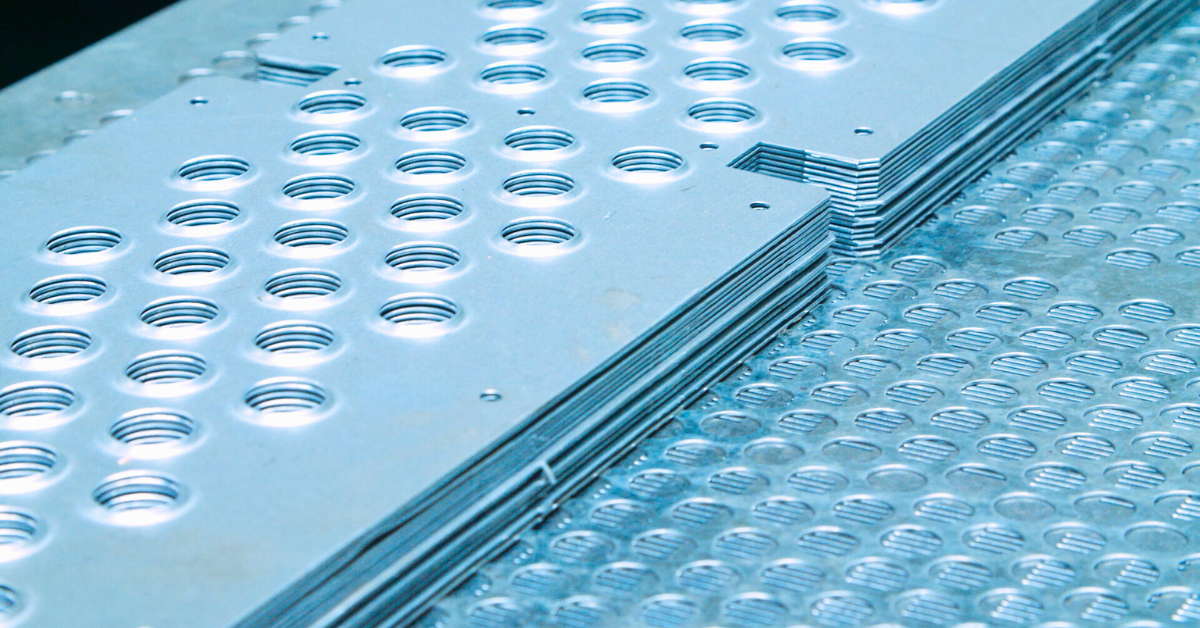

Precision metal stamping is a cornerstone of industrial manufacturing, relied upon by industries such as power distribution, appliances, and durable medical equipment for high-accuracy, repeatable parts. Consistency in metal stamping is critical, as even slight dimensional deviations can lead to functional failures, assembly issues, and field service concerns.

At Miro Manufacturing, we have spent over 30 years refining our expertise in precision metal stamping, ensuring our customers receive high-quality components every time. But what factors influence consistency in precision metal stamping? Let’s explore the key elements that affect stamping precision and how Miro Manufacturing maintains the highest standards in the industry.

Material Properties: The Foundation of Precision

The materials used in metal stamping play a crucial role in determining part consistency. Selecting the right material ensures predictable performance throughout production. Key material properties to consider include:

Hardness

Harder metals require greater force to shape, which increases tool wear over time. This can lead to minor variations in part dimensions if not properly managed.

Ductility

Highly ductile materials deform more easily, making them ideal for intricate stamping operations. However, excessive ductility can result in inconsistent material flow, leading to dimensional variation.

Wear Resistance

Metals with high wear resistance tend to be more durable but may require specialized tooling to maintain precision during high-volume production.

Common Materials Used in Metal Stamping

Miro Manufacturing is capable of stamping materials in thicknesses ranging from 0.005” to 0.5”, including:

- Aluminum

- Brass

- Copper

- Hastelloy®

- High-strength, low-alloy steel

- Stainless steel

- And more

Press Accuracy: The Heart of Precision Metal Stamping

The accuracy and repeatability of a stamping press directly impact part consistency. Variations in press speed, tonnage application, and mechanical wear can introduce inconsistencies over time. Miro Manufacturing’s extensive capabilities set it apart as a leader in accommodating diverse customer needs with presses ranging from 60 to 1,000 tons, bed sizes from 21″ x 32″ to 61″ x 148″, and coil handling up to 20,000 pounds. Our 660-ton press is capable of producing up to 40 parts per minute, while our 330-ton Komatsu servo press offers precision engineering and digital controls for maximum accuracy and repeatability. (For full specifications of all our machines, download our equipment list.)

Miro’s stringent quality control measures and process monitoring help mitigate variables to sustain precision in every stamped part.

Equipment Calibration: Precision Requires Expertise

Even the most advanced equipment requires regular calibration to maintain stamping accuracy. Over time, tooling wear, misalignment, and mechanical shifts can degrade precision. This is why Miro Manufacturing places a strong emphasis on meticulous equipment calibration. Our technicians conduct routine maintenance and precision checks to ensure every press operates at peak performance.

Miro is ISO 9001:2015 certified, demonstrating our commitment to quality. Our Micro-Vu Excel 1054 vision system and FaroArm coordinate measuring systems enable high-precision inspection throughout production. We are experienced with PPAPs, control plans, FMEAs, and capability studies, ensuring stamped parts meet stringent requirements.

Material Sourcing: Ensuring High-Quality Inputs for Consistent Outputs

Quality starts with the materials used in production. Poorly sourced or inconsistent raw materials can lead to defects and inconsistencies in stamped components. Miro Manufacturing partners with reliable material suppliers to ensure uniformity in every batch. Our rigorous incoming material inspections verify that each sheet or coil meets the required specifications before it ever reaches the press.

Partner with Miro Manufacturing for Contract Precision Metal Stamping

Achieving consistent precision in metal stamping requires a combination of expertise, technology, and stringent quality control. At Miro Manufacturing, we bring transparency, decades of experience, and technical excellence to every project. Our one-stop-shop approach—from material selection and tooling design to final stamping and quality inspection—ensures that every part meets the highest standards.

With over 30 years in the industry, we understand that our customers rely on precision and repeatability to keep their production lines running smoothly. Our collaborative approach, advanced equipment, and in-depth expertise make us the ideal partner for your precision metal stamping needs.

Contact Miro Manufacturing today to request a quote and experience the difference precision makes.