Incredible Precision

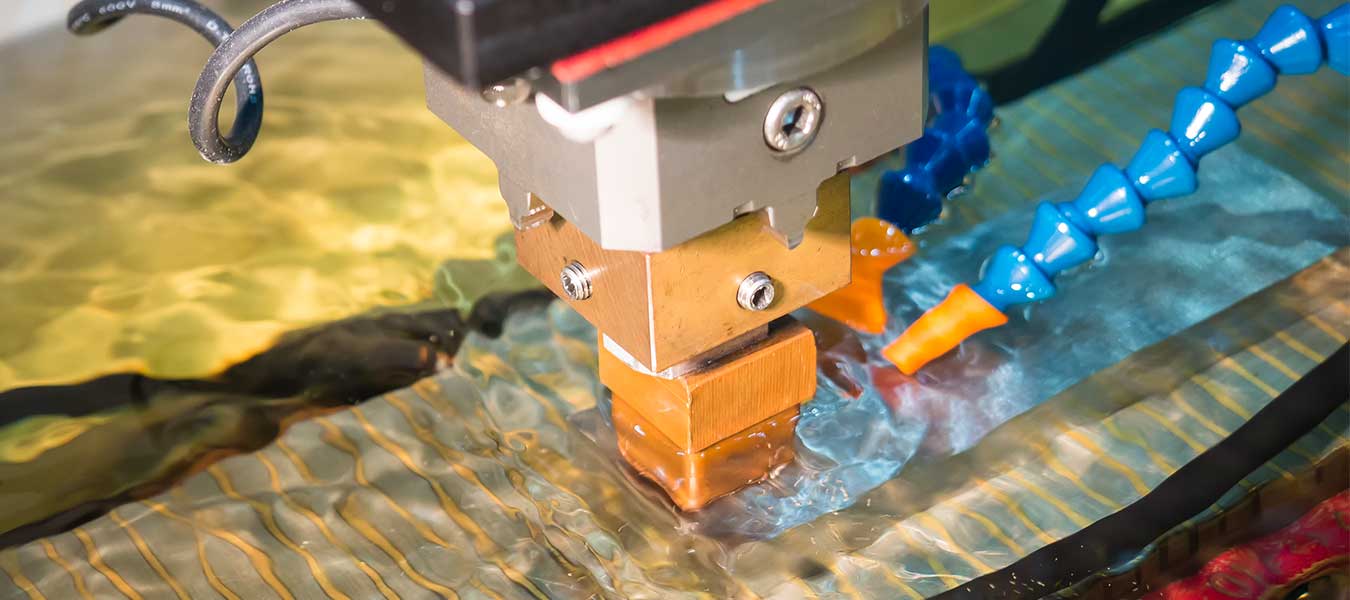

Miro Manufacturing’s electrical discharge machining services use state-of-the-art submersible wire EDM machines to produce die and mold tooling components as well as prototype and production parts.

Wire EDM Cutting Capabilities

We utilize wire diameters of .010” to .012” yielding a tolerance of ± .0001. Our wire EDM machines have a travel of 20″ x 14″ x 12″ (X Y Z). Equipped with automatic wire threading, our machines are able to operate 24 hours a day.

Small Hole EDM Drilling

We offer small-hole EDM drilling to produce start holes, machine blind or through holes, or to remove broken taps. Our equipment has the capability to drill holes from .010” to .125” diameter in hardened steel.

Common Wire EDM Applications

Wire EDMs are able to cut aluminum, brass, bronze, carbide, stainless and tool steels. Gears, sprockets and splines lend themselves well to the wire EDM process.

Wire EDM Services for Projects of All Sizes

Combining our EDM manufacturing ability with our other cutting, forming and machining capabilities will simplify multi-process projects. Whether your requirements consist of a single, one-of-a-kind component or ongoing production quantities, consider Miro for your wire EDM needs, as well as a single source supplier.

Located in Waukesha, near Milwaukee, Miro provides wire EDM services throughout Wisconsin and the United States.

Contact Miro Manufacturing online for more information, or request a quote to get started.

View our “Capabilities and Equipment List” for a complete list of our wire EDM equipment.