Miro Manufacturing prides itself on being a comprehensive partner throughout every phase of the production process. That process begins with the initial design discussions and moves meticulously through engineering and custom metal fabrication, all the way to the shipment of completed products tailored precisely to your specifications. Our fabrication offerings include laser cutting, waterjet cutting, forming, welding, and assembly.

Laser and Waterjet cutting

Our diverse cutting services show our commitment to quality, and they cater to a variety of needs and budget considerations. That way we ensure every project is handled with the utmost care and efficiency. We utilize cutting-edge laser and waterjet technology, supported by advanced nesting software designed to optimize material use, thereby reducing waste and keeping costs in check.

Our laser cutting services can handle aluminum thicknesses of up to ½ inch, stainless steel up to ¾ inch, and carbon steel up to 1 inch, with the capability to process sheets as large as 60 by 120 inches.

Additionally, our waterjet is versatile enough to cut nearly any material and achieve maximum cutting thicknesses of 7 inches, with a generous sheet size capability of 72 by 144 inches, making it an ideal solution for complex projects.

For applications demanding extraordinary precision, our wire EDM machining service stands out, showcasing our dedication to delivering exceptional results.

Forming

Miro’s state-of-the-art CNC press brake capabilities include with multiple work centers and capacities:

- Up to 360 tons

- Bed lengths reaching 14 feet

- Bending for up to ½” thick material.

Our press brake systems include electrically powered CNC tables that enhance the handling and forming of large sheet metal parts.

Welding

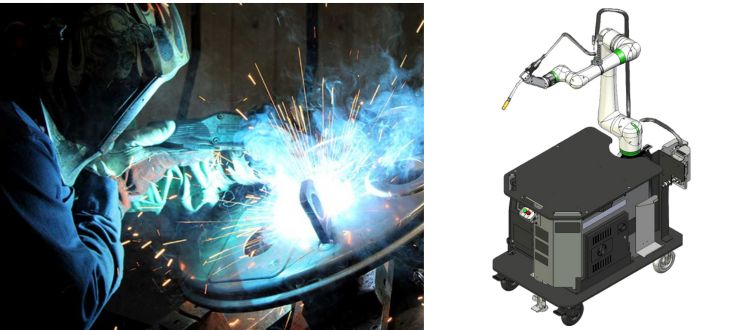

Miro is adept in employing advanced techniques to meet the diverse needs of our clients. Miro adheres to exacting specifications, ensuring precision and quality in every project. Our state-of-the-art welding technologies encompass a variety of methods including MIG, TIG, spot, stud, and rotary welding, each chosen based on the specific requirements of the task at hand.

These techniques allow Miro to tackle a broad spectrum of material types, including carbon and stainless steels, aluminum, and more, making it a versatile partner in custom metal fabrication and manufacturing processes. Furthermore, Miro’s innovative approach includes the integration of cobot weld automation to enhance efficiency, consistency, and safety in operations, reflecting a commitment to the latest technological advancements in the field.

Our versatility extends beyond materials: Miro is equipped to work with multiple material shapes such as sheet, plate, tube, pipe, bar, structural components, and angle stock, delivering tailored solutions that meet the demanding standards of contemporary industries. Through Miro’s comprehensive welding capabilities, clients can expect not just superior craftsmanship, but also a collaborative partnership that prioritizes their unique challenges and specifications in every weld.

Assembly

Assembly is a critical phase in the product development lifecycle, and at Miro, we understand that each project necessitates a tailored approach to meet specific requirements. Whether you are assembling a subcomponent for a larger system or producing a complete product ready for consumer markets, our adept team handles all aspects of assembly with precision and efficiency.

We take pride in utilizing state-of-the-art equipment to ensure that every assembly process is executed smoothly and effectively. Our facilities are designed to accommodate a variety of assembly needs, allowing for flexibility and customization.

Additionally, our commitment to quality assurance means that each product undergoes rigorous inspection before it reaches the packaging stage, ensuring that it meets both our high standards and your expectations. Our consumer-ready packaging capabilities ensure that we present your product in an appealing manner that enhances marketability.

Custom Metal Fabrication: The Miro Difference

It’s crucial to select the right contract manufacturer, especially when your success may require adjustments in the manufacturing process to control costs and exceed expectations. By opting for Miro as your single source supplier, you not only simplify your supply chain but also gain access to a comprehensive suite of services that can adapt to your evolving needs.

From concept to completion, Miro Manufacturing embodies the ethos of being your partner “From Start to Part,” dedicated to streamlining operations and enhancing productivity. With Miro at your side, you can confidently navigate the complexities of manufacturing—maximizing efficiency and reducing costs—all while maintaining the quality and standards your customers expect. Choose Miro Manufacturing to be the right partner for the right job.